Material: Stainless Stell

Color: Silver

Usage: Cages for Mice / Rats / Guinea Pigs

1. Product Application:

The fully automatic cage box washer is designed for the laboratory animal industry and is applicable to the automatic cleaning, disinfection and drying of animal cages, drinking bottles, feed boxes and other utensils in laboratory animal breeding.

2. Standardized Cleaning:

The cleaning process is controlled by an automatic program and key cleaning parameters are monitored to achieve automated and standardized cleaning of items;

The cleaning effect of different batches and each cleaning point in the same batch is consistent;

The cleaning data can be traced and managed.

3. Function Introduction:

High Efficiency:

- Equipped with a preheated water tank to reduce the preparation time for water heating;

- The rapid cleaning program can complete one cleaning cycle in 4 - 6 minutes to meet the need for rapid cleaning;

- It can clean up to 40 mouse IVC cage boxes at a time.

Good Cleaning Effect:

- Adopting an independent pipeline design for cleaning and rinsing to ensure that there is no residue on the surface of the cleaned items.

- Using an original imported European circulation pump with a large circulation volume design, strong spray force, stable quality and effectively improving the cleaning effect.

- The patented spray arm uses a fan-shaped water curtain spray to clean the outer surface, ensuring a 360-degree dead-angle-free cleaning of the utensils.

- The cleaning aids are automatically and quantitatively added by a peristaltic pump to ensure the consistency of cleaning data.

Low Energy Consumption:

- The final rinsing water is used for the next cleaning to save water;

- The outside of the cleaning chamber and the preheated water tank are pasted with thermal insulation materials to effectively reduce heat loss and noise.

Control System:

- The human-machine interface is a 7-inch color liquid crystal touch screen, which is convenient to operate;

- The Siemens PLC programmable operating system is stable and reliable, anti-magnetic and anti-breakdown; the control system is independently designed and developed to meet various operation and management requirements;

- Parameters such as cleaning temperature, time and the amount of cleaning agent added can be set by oneself;

- The liquid crystal screen displays the current operation steps and working parameters in real time;

- It has a power-off memory function. In case of power failure during the program execution, the equipment can continue to execute the program state before the power failure until completion after power is restored.

- Alarm Function: Overheating of the circulation pump, abnormal water heating, abnormal air heating, lack of cleaning liquid, abnormal water inlet, etc.

Structure:

- The outer shell is made of 304 stainless steel, which is corrosion-resistant, durable and easy to clean;

- The cleaning chamber is made of mirror 316L stainless steel to reduce residues, and has a bottom sloped structure to improve the efficiency of circulating return water;

- The double-layer hollow tempered glass door is heat-insulating, noise-reducing and easy to observe.

Program:

- The cleaning function has 10 standard programs, and the cleaning parameters of each can be independently set and modified. There are also 100 custom programs that can be independently named in Chinese, English, numbers, etc.;

- Manual Program: Manual testing and operation can be realized, providing greater freedom;

- Disinfection Program: Thermal disinfection can be achieved, and the disinfection level can be displayed and calibrated in real time through the A0 value.

Safety Protection:

- The equipment is equipped with an emergency stop switch. In case of an emergency, the power supply can be immediately cut off to stop the equipment from running;

- The equipment has a real-time leakage monitoring function;

- The sealing door has a safety protection device. It will automatically stop when encountering obstacles during the operation to prevent accidents;

- After the equipment starts cleaning, the door will be automatically locked and cannot be opened. Only when the whole process is completed and the temperature drops can the door of the chamber be opened.

4、Technical parameters

Model | CTCW-1500 | CTCW-1500Z |

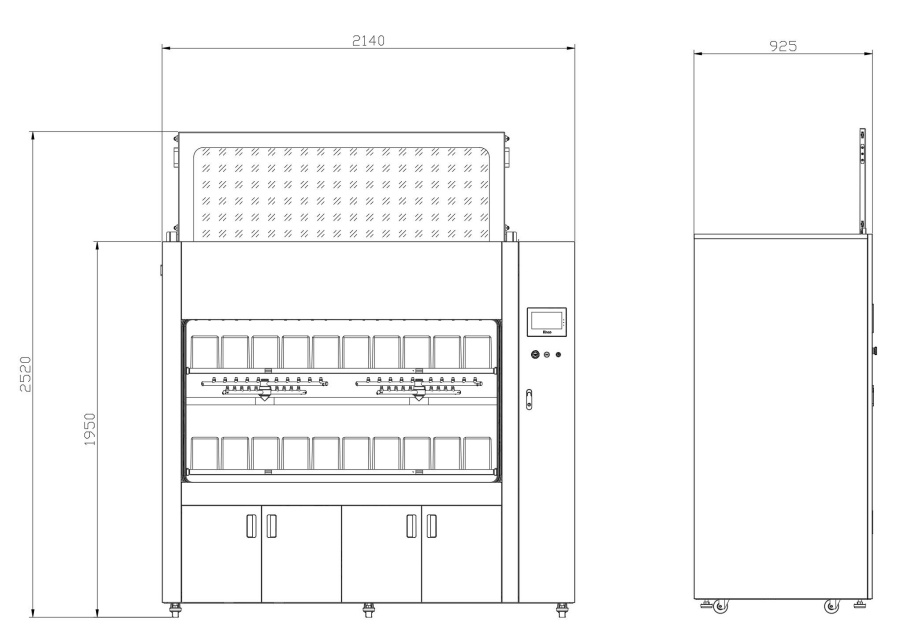

External Dimensions(W*D*H)mm | 2140×925×1950 | |

Inner Chamber Volume | 1500L | |

Control System | PLC/Siemens | |

Touch Screen | 7寸 | |

Cleaning Capacity | Can clean up to 40 mouse IVC cage boxes at most | |

Cleaning Time | The rapid cleaning program takes 4 - 6 minutes | |

Door Opening Method: | Automatic lifting door | |

Cleaning Temperature | >60℃(adjustable) | |

Rinsing Temperature | >82℃(adjustable) | |

Drying Temperature | Room temperature ~ 120℃ (optional) | |

Heating Method | Electric heating | Steam heating |

Power Supply | AC 380V/50Hz 34kW | AC 380V/50Hz 4kW |

Steam Source | / | Pressure:0.3-0.5Mpa,Flow Rate: 50Kg/h |

Water Source | Water Source: Softened water: Pressure: :0.2-0.5Mpa, Flow Rate: 25L/min | |

Compressed Air Source | Pressure: 0.5~0.7Mpa ,Flow Rate: 100L/min | |

5、Outer dimension:

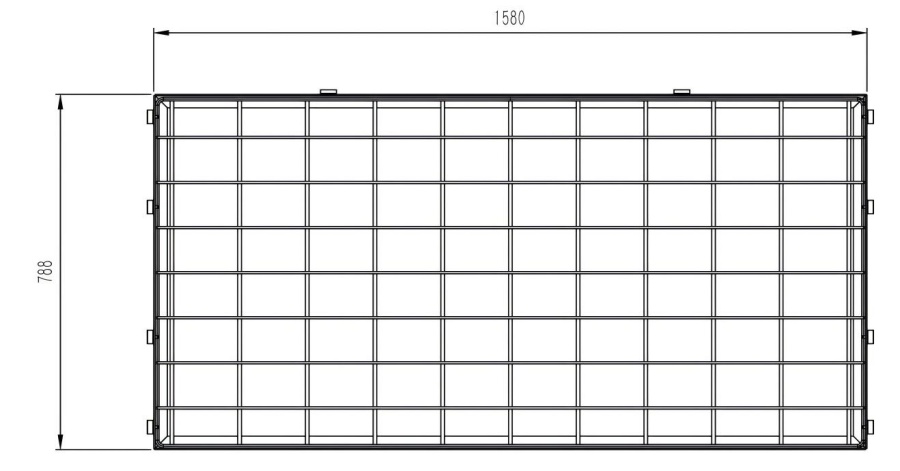

6、Outer dimensions of cleaning rack:

7、IVC cages commonly used in the market::

Item | Cage model | size/:L×W×H(mm) | Quantity of cleaning(piece) | mark |

1 | VM370A mice cage | 370×157×180 | 40 | |

2 | VM315A mice cage | 315×205×180 | 34 | |

3 | VM390A mice cage | 390×180×180 | 32 | |

4 | M330A mice cage | 330×205×180 | 28 | |

5 | VM372A mice cage | 372×213×175 | 28 | |

6 | R420A rat cage | 420×250×230 | 18 | |

7 | VR470B rat cage | 470×315×260 | 12 |